AGM battery, also known as VRLA battery, is a sealed valve-regulated lead-acid battery with AGM material as the separator. There are mainly three types. One is used as a starter battery for automotive due to its high current performance. One is focused on deep cycle performance, used in solar & renewable energy, UPS backup power, telecom base stations, CCTV, and other BESS(Battery Energy Storage System). The 3rd type is focused on higher current discharge as for motive power.

Deep cycle AGM battery is a type of VRLA battery focused on deep cycle performance. Sealed, maintenance-free, the biggest advantage, excellent deep cycle life, achieve more than 1000 cycles at 50% DOD.

AGM battery is very sensitive to overcharge and over-discharge, improper charging and discharging will lead to the reduction of battery life. So the proper charging process is very important.

The Charger

If you are using a VRLA battery smart charger, it is certainly the best choice. Can we use a regular charger?

Well, it depends. You have to be very professional and careful, as well as follow the principle of three-stage charging.

The whole process could be very complicated, so in general, it is still recommended to have a dedicated smart charger.

Three Stages Charging

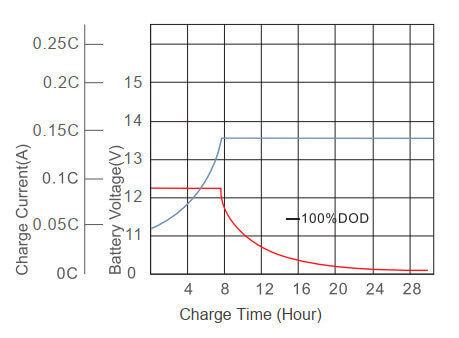

The THREE STAGES CHARGING are Constant Current charge (bulk charging), Constant Voltage charge (absorption charge), and Supplemental charge (float charging).

The 1st stage is constant current charging, CC for short name. We set the charger voltage to the battery (pack) cycle charge voltage, and the current to the cycle charge current. Please note that too high voltage or too high current will overcharge the battery and damage the battery. The specific voltage and current will be explained in detail in the next 2 parts. During this phase, the battery voltage rises to a constant number.

The 2nd stage is Constant Voltage, where the battery voltage remains at a constant value and the charge current decreases. After the current is reduced to a very small value, stage 3 begins, reducing the voltage to the float voltage.

The 3rd stage is supplemental or trickles charge. The battery current is shallow, and this phase is critical to activate the whole materials inside the battery, which helps to maintain a good health condition of and extend the lifetime.

For more detailed information, please visit this link:

https://batteryuniversity.com/index.php/learn/article/charging_the_lead_acid_battery

Charge Voltage

The charge voltage includes cycle charge voltage and float charge voltage, fast charge voltage. In general, the float charge voltage is used for daily floating charges, the lowest. Cycle charge voltage is used for recharging after discharged to a certain depth, it is higher. Fast charge is the voltage of rapid full charge under an emergency condition, the highest, not commonly used.

The nominal voltage of a single AGM battery cell is 2V. In different combinations, the popular voltages are 2V, 6V, 12V. 24V and 48V are also found in battery banks. Specific cycle charge voltage and float voltage refer to the following table. All parameters are generally based on 25°C. Please note that the appropriate voltage is different for flooded or gel batteries.

| Battery(Bank) Voltage | Cycle Charge Voltage | Float Charge Voltage |

| 2V | 2.40V~2.50V | 2.25V~2.30V |

| 6V | 7.20V~7.50V | 6.75V~6.90V |

| 12V | 14.4V~15.0V | 13.5V~13.8V |

| 24V | 28.8V~30.0V | 27.0V~27.6V |

| 48V | 57.6V~60.0V | 54.0V~55.2V |

On regular basis at 25°C for 12V deep cycle AGM batteries, float charge voltage is 13.5V~13.8V, cycle charging voltage is 14.4V~15.0V.

Some batteries are marked with charge voltages on the label or print, including float charge voltage and cycle charge voltage. For example, as shown in the above photo, the float voltage is 13.5V~13.8V, and the cycle charge voltage is 14.4V~14.9V. You can use the charge voltage directly. Or you can also choose the safer intermediate value or minimum value. The highest value of the cycle charge voltage (15.0V) could be considered as the fast charge voltage, which is always considered to cause damage to the battery.

Temperature Compensation

Temperature compensation is -30mV/°C for cycle charge voltage, -20mV/°C for float charge voltage

At low temperatures, the charge voltage may be slightly higher. When the temperature is high, it is extremely important to be careful of overcharging due to high voltage.

Conditions without Print

If the charge voltage is not indicated on the battery, the reasonable cycle charge voltage can be estimated according to the open-circuit voltage (OCV) when the battery is fully charged. Generally, the open-circuit voltage of the 12V battery when fully charged plus 1~1.5V is a reasonable cycle charge voltage.

If you do not know the open-circuit voltage when the battery is fully charged, you can occasionally charge with 2.4V per cell blindly, but it is more difficult to judge when the battery is full. There may be overcharge, causing certain damage to the battery. Note that it’s 2.4V per cell, NOT 2.4V per unit.

If you only need to charge the battery once in the way described in this article, you can skip this step. If you want to use it for a long time, it is recommended to perform this step carefully to determine the open circuit voltage when the battery is 100% fully charged. We call it as OCV (open circuit voltage) at 100% SOC (stage of charge).

There are several ways to know this value:

First, use a DC voltmeter to measure the voltage of the battery that remains more than one hour after fully charged, and the value is directly obtained.

Second, get from the documents. The value will not be printed on the battery, but usually we can get it from the manufacturer’s operating instructions or MSDS.

Third, for a flooded battery, it can also be obtained by testing the density of the electrolyte of the battery when fully charged. The method is OCV=SG+0.84, for example, the density of the electrolyte is 1.35 g/mL, and the open circuit voltage of the battery is OCV=1.35+0.84=2.19V.

It is important to get the voltage when the battery is fully charged. It can be used to verify that if the battery is fully charged, to determine the battery charge and the depth of discharge.

Charge Current

The charge current is related to the rated capacity of the battery. It is generally 0.1C~0.4C, which is 1/10 to 4/10 of the rated capacity.

If it is a 100Ah battery, it is 10A~40A. It can be measured with a DC ammeter, a clamp meter.

Well, some of the most advanced manufacturers on the market today use thin plate technology. They increased the charging current to 1C, which is equal to the rated capacity. High-current charging will greatly shorten the charging time, but these high-end batteries are not popular enough.

Still, 0.1C~0.4CA are considered in most of the applications.

Charge Temperature

The charge temperature of AGM battery is between 0℃ and 40℃, please keep the charging temperature within this range, otherwise, it is harmful to the battery.

Battery Capacity

Battery Capacity can also be found from the print o label.

In general, the print will indicate the rated capacity of the battery, as shown in the photo, the battery is marked as 200Ah, but the UPS battery is sometimes represented by W. For this kind of battery, the simple calculation method is the wattage divided by four.

Charge Connection

There is not much to say, the positive pole of the charger is connected to the positive pole of the battery, the negative pole of the charger is connected to the negative pole of the battery, then the charger and the mains are turned on, then the battery is charging.

It is worth mentioning that for multi-cell battery charging, I recommend parallel charging. Because parallel charging can improve the consistency of the battery, and low-voltage charging is also safer.

It should be noted that when charging in parallel, the cable should adopt the diagonal method to improve the consistency of the current shunt. The so-called diagonal connection method is as follows.

Determine the charging time, or when to stop charging

If it is not blind charging or charging with an excessive voltage, the charging current is reduced as charging progress.

If the battery is charged by the manufacturer’s recommended charge voltage, in general, the charging current can be considered to be fully charged when it is reduced to 0.03C. For example, a 100Ah battery, if using the voltage recommended by the manufacturer, is considered to be substantially fully charged when the charging current is less than 3A.

Alternatively, the time required to charge 1.2 times the required amount of power is the charging time. For example, a 100Ah battery, fully discharged, needs to be filled with 100Ah to be full; 1.2 times 120Ah; if the charging current is 0.15C or 15A, then 120÷15=8 hours can be almost fully charged.

Some cases during charging

The battery is warm.

During any stage of charging, if you feel the battery is warm to your touch, it is normal, no need to worry.

But if you feel it is very hot, even like burning, you have to stop charging immediately or reduce the charging voltage or current, or both.

A sound like bubbling.

Energy is released in the form of heat when the current passes through the electrolyte causing the water particles to break down. H2 is released, O2 is released, and steam is released. There are other gases like hydrogen sulfide that smells like rotten eggs, it is toxic (especially in a small room). That’s why it is important to keep the battery room ventilated.

If the VRLA batteries are making a bubbling sound but are still within safe charging range, they should be able to recombine the evaporated electrolyte internally. If there is a hissing sound, then you know that it’s gone too far and have to lower the voltage or current or both of them. Or stop for a while and then re-try.

Constant Current Stage only allows the cells to reach 80% SOC. The Constant Voltage Phase is to get the cells to 99%, where some slight bubbling is acceptable. Be sure to monitor the battery voltage and temperature and keep it below 35℃ and ensure that all battery cells have plenty of electrolytes.

Charging in Systems

Solar & Renewable Industry

Victron Charge Controller

For Solar Charge Controller, it will perform 3 functions:

1. Regulate the output charge voltage, converting the unstable voltage generated by the solar panel into a stable charging voltage out. It also follows the three-stage principle.

2. Monitor the battery voltage. If the battery voltage is too low, cut off the load.

3. Cut off if there is reverse current at night.

UPS chargers and other energy storage system charging equipment, also have similar functions of regulating voltage, protecting batteries, and cutting off the reverse current.

Important Notes

Watch your charging voltage and charging current

Pay attention to special events, stop charging or lower the voltage or reduce the current in time.

Summary

If you are in AGM / VRLA battery business, it is quite important for you to be experienced in the charge & discharge, it will help to extend your battery life and gain more trust during the sales.

Another useful kit to extend the life of batteries in series is the balancer, for more details please check the below link:

25 Responses

Hi Andy.

I have 2 x Vision 12volt 200 amp AGM batteries in series, running my fridge. I have a Victron mppt with 1400watt panels on to give 24 volt to batteries. How long should the absorbtion charge be. ( I set it for 1hour 14.4 volt) I use only 15% of battery capacity. Voltage early in the morning is 12,4 volt.

Hi Deon,

14.4V is a good voltage for the absorption stage (Constant Voltage).

1 hour for the absorption stage is enough for a regular charge.

1400 watt if 24V output, deducted the line loss, the current is around 50A.

The whole battery 200Ah can be charged from empty to full in 5 hours.

If the static voltage of one battery in the morning is 12.4V, means the remaining energy is 70% to 80%.

Andy

A great article Andy. Handy & informative. You’ll have to change your name to “handy andy” now! This article shows also that the chinese industry is maturing, with great tech resources. Pls pass onto the chinese sunon people, congratulations & a thank you from an aussie user for their atrtention to details & sharing their knowledge, with us mere plebs.

Again thanks,

Beejay from AUSSIE

Thank you very much, Beejay.

Andy

Hi Andy,

I am in the process of connecting 2 x 200ah wired in series to 24v vision batteries to an Axpert 3kv inverter.

But I need help with the battery settings. The supplier instruction sheet is very brief and not too user friendly

Hi Barry,

24V200Ah battery pack is ok to support 3kVA inverter, but it is not good to support a constant 3kW output over half an hour.

About the battery settings, do you mean the protection voltages?

For your condition, you may set the low-end voltage to 23.80V (11.90V per unit), and the high-end voltage to 29.2V (14.6V per unit).

Andy

Hi Andy, I was given a soggy 36AH GEL battery to charge. The open circuit voltage was 12.5 and I put it on charge. It quickly went to float and I left it for a while but the open circuit voltage went quickly down to 12.5 again without a load.

I then went to trick the charger but instead of placing a good battery in parallel, I placed a 30 Ohm resistor across the charger to make it think the battery needed to be charged.

I notice the charger is going from CHARGE to FLOAT repeatedly every 5 to 10 seconds for hours on end.

Do you know why this happens? Is there some chemical reaction going on like de-sulphating?

Hi Peter,

When the charger thinks the battery is full, it will switch to float mode.

It means the battery reaches a voltage of 14.6V(it may be different for different chargers) or a very small current such as under 10mA.

Then without a charge current, the battery voltage will drop.

If the battery voltage is under 13.8V, the charger will switch back to charge mode.

Open circuit voltage of 12.5V can be full for some batteries, have you ever tried to discharge the battery?

For your condition, 5-10 seconds switch from charge to float, maybe the battery cannot be charged.

The battery voltage rises and drops too quickly.

Andy

Hi Andy,

I am writing from Africa were we have hot temperature. I’m using solar not electricity and my panel is of 150amp with a battery of 100amp but within three months of installation I cannot even watch tv but my bulbs are working effectively.what type of batteries,inverter and charge controller can you recommend for me because the AGM batteries are available here I show them in one store

Hi Andy

I Want watch tv for at least 10hours.

What solar system would you recommend me for

Hi Amadou,

If your TV is 200W, then 10 hours will need 2000Wh energy.

It equals one battery 12V166Ah, for 50% DOD you will need battery 12V300Ah.

5 hours’ sunshine, 400W solar panels are necessary.

Please note, the numbers are actual parameters.

Andy

Hi Andy I have a bosch AGM 680cc ln2 . Which setting on smart battery charger 7 stage _ gel calcium or lead acid . Which setting to put it on

Hi Joe,

Since your battery is 680CC, I think your battery is a car battery, a type of lead acid battery, not gel.

To make sure of your charge option, you may read on the battery or the manual about the charge voltage.

Ensure the charger’s output voltage is within your battery’s charge voltage range.

Andy

Hello.

Please help if you can,become can’t find answer?

I have inverter 3.2kv 24v and 2x140Ah AGM batteries.

What parameters should be?

Bulk charging voltage-

Floating charging voltage-

Low battery cutoff voltage-

Thank you.

Hello Max,

For 24V systems, with 2 AGM batteries in series, below are the recommended related voltages:

Bulk Charge Voltage: 29.2V

Float Charge Voltage: 27.0V

Low Battery Cut Off Voltage: 23.0V

@25℃

Andy

Hi. I’m expanding a battery bank, with 50Ah AGM batteries, from 6 to 12. I have the original 6 in parallel because my inverter and other devices (like lights and phone chargers) are 12 volts. I’m planning on dividing them in 6 banks of 2 and connect them to positive and negative busbars to balance the charge. Will this be the wright way to do it? I know it seems kind of weird to use this array but, this are the only type and capacity of batteries I can get within my budget. Also, I read about using diodes, but I don’t know if they are required. If so, what type and capacity should be used? Thank you.

Hola Jose,

I think so.

It is recommended NOT to mix old and new batteries, but in parallel connection is OK.

As in small current conditions, the old and new batteries will all be working.

But it is really not good to use in series connection, the exceeded energy in new battery will be wasted.

Andy

Hi Andy,

I need your help. I am from Africa and running 4 X 12 volts 120 AH gel batteries. Cycle use is 14.4 to 15.0 volts at 25°C. What settings do I use for the below on the 5.5KW inverter.

Bulk charging voltage:

Floating charging voltage:

Low DC cut-off voltage:

Hi Luwa,

If your batteries are connected in series for 48V, the recommended settings are as below:

Bulk Charge Voltage: 59.6V

Float Charge Voltage: 54.0V

Low DC Cut-off Voltage: 40.0V

You can also set the Low DC Cut-off voltage a little bit higher to 44.0V for a longer usage lifespan.

Andy

Hi Andy,

I was wondering if you might know why the bulk charge voltage on my inverter will not go higher than 51.0 V when in settings I have specifically indicated Charging Voltage to be 58 V. I have 8 – 6V AGM batteries connected in series. The inverter is EG4 6000XP. The batteries are new. (one year old, just put into use). Do you think it is the fault of the batteries?

Hi Scott,

If the batteries are in charge state, the circuit will reach the charge voltage.

Even if the batteries are broken, it will show the charge voltage.

(Battery terminals and charger terminals are connected.)

If the batteries are 51V in an open circuit state (a while after being charged to full), it is okay and perfectly fine for a 48V lead acid battery bank at nearly 100% SOC.

Andy

Thank you Andy! My batteries will not charge at 58V. They charge at 51V no matter how long I am charging them through the inverter. I can’t seem to get them to charge at 58V…

Hi Scott,

Do you have a voltage meter? You can have a voltage reading by the inverter charge socket to see the value of the charge voltage.

If the battery voltage 51V is shown on the inverter screen, it may be right to display the static voltage (open circuit voltage).

Andy